2026-01-17

2026-01-17

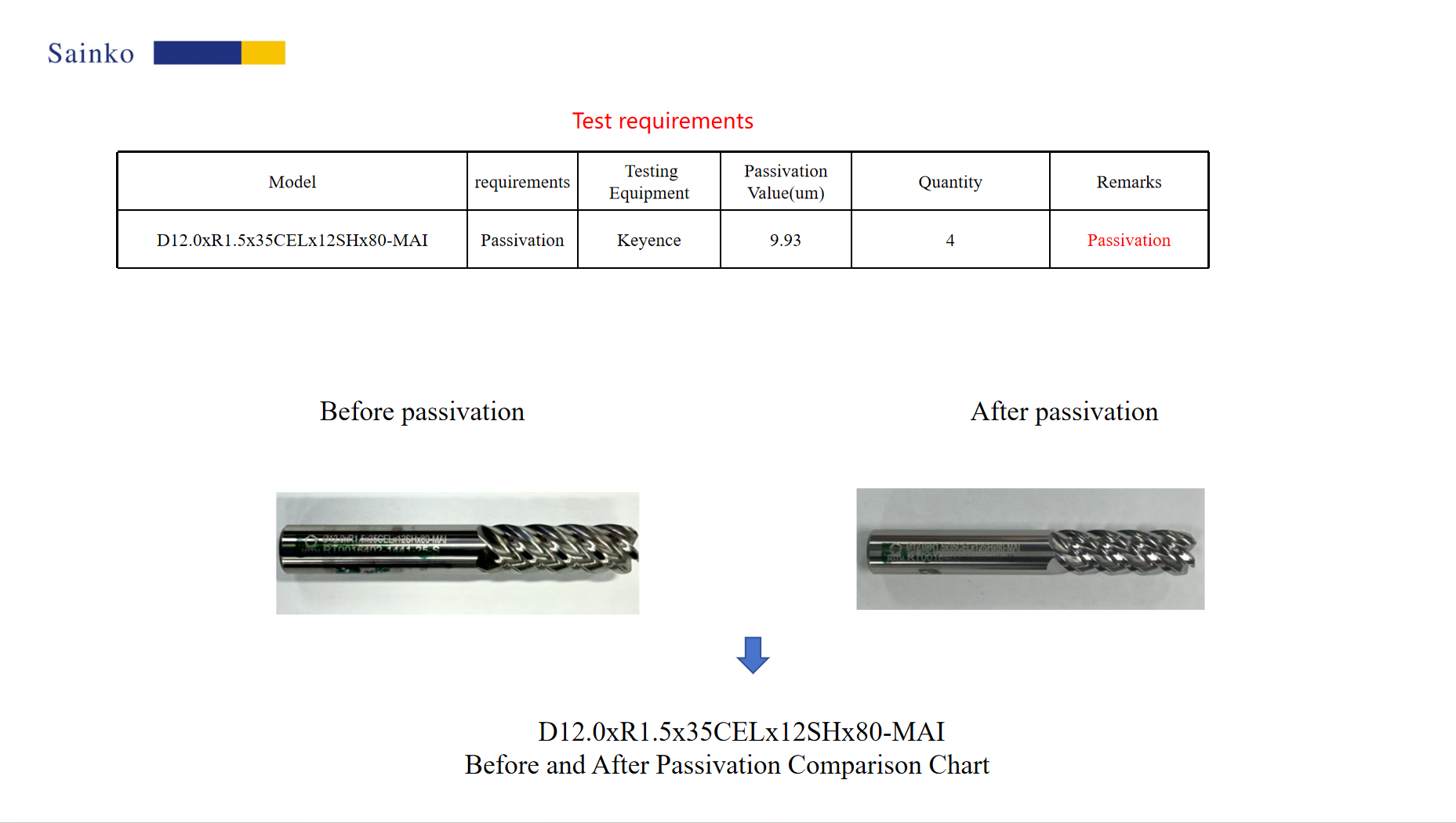

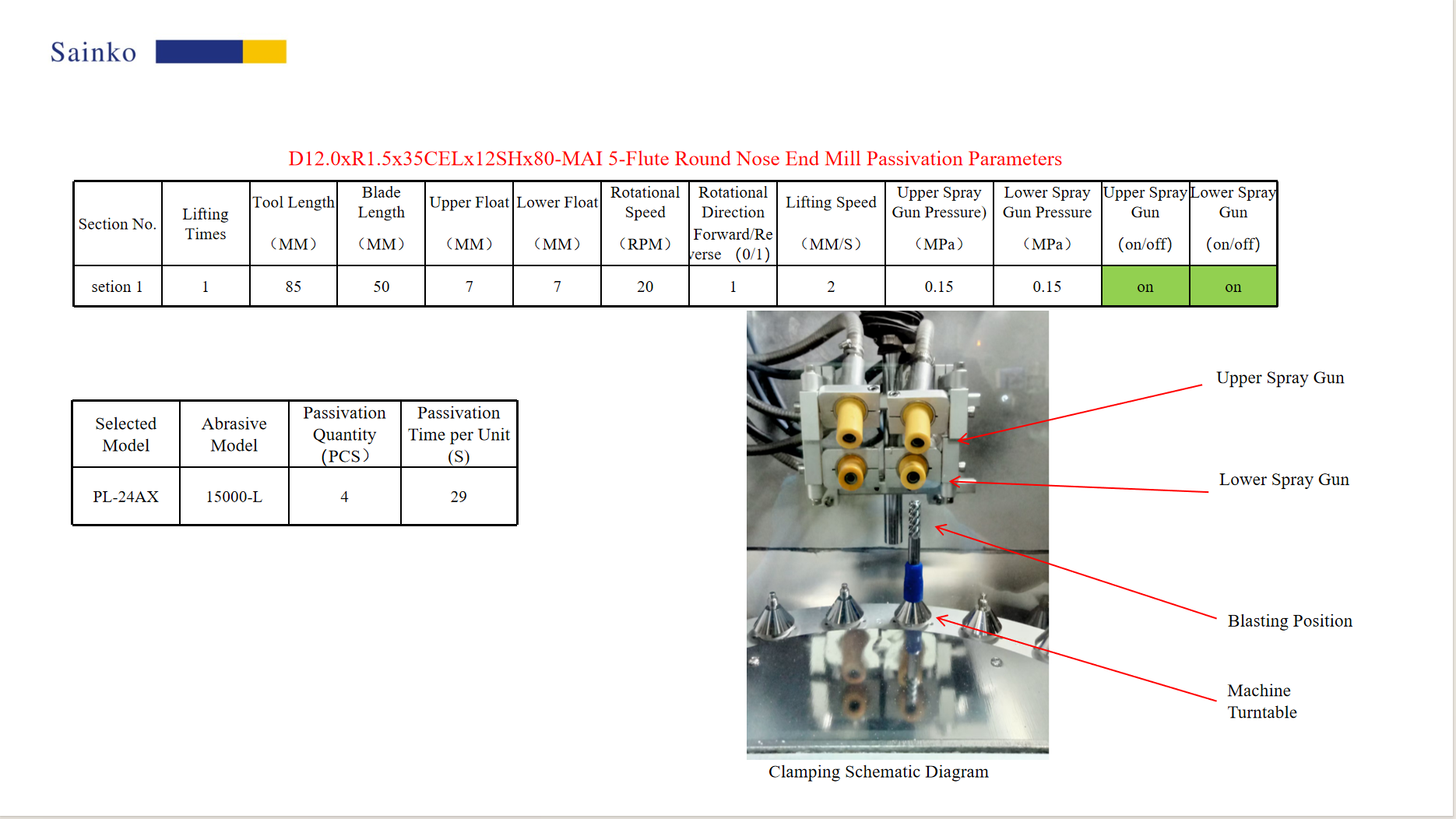

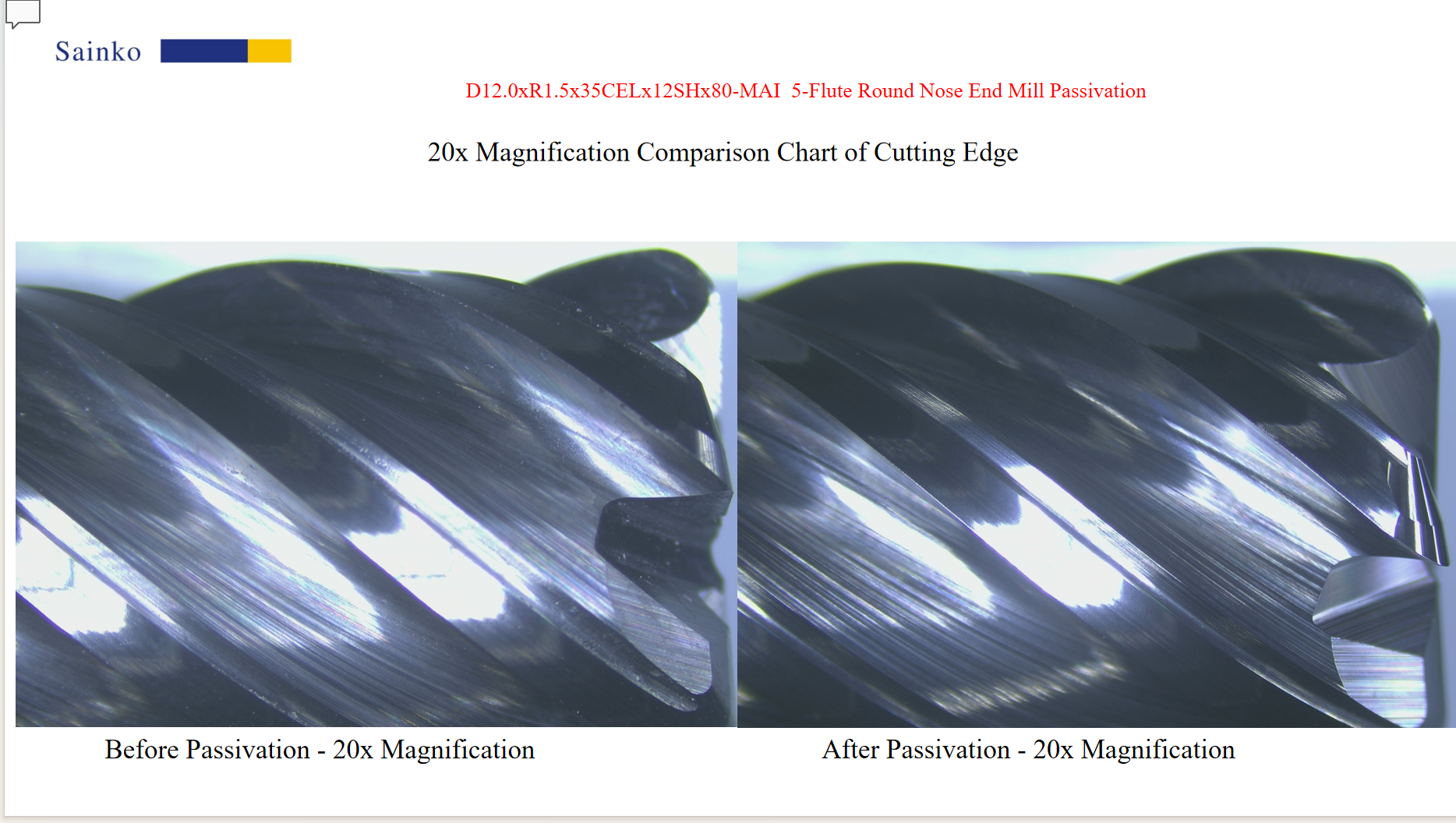

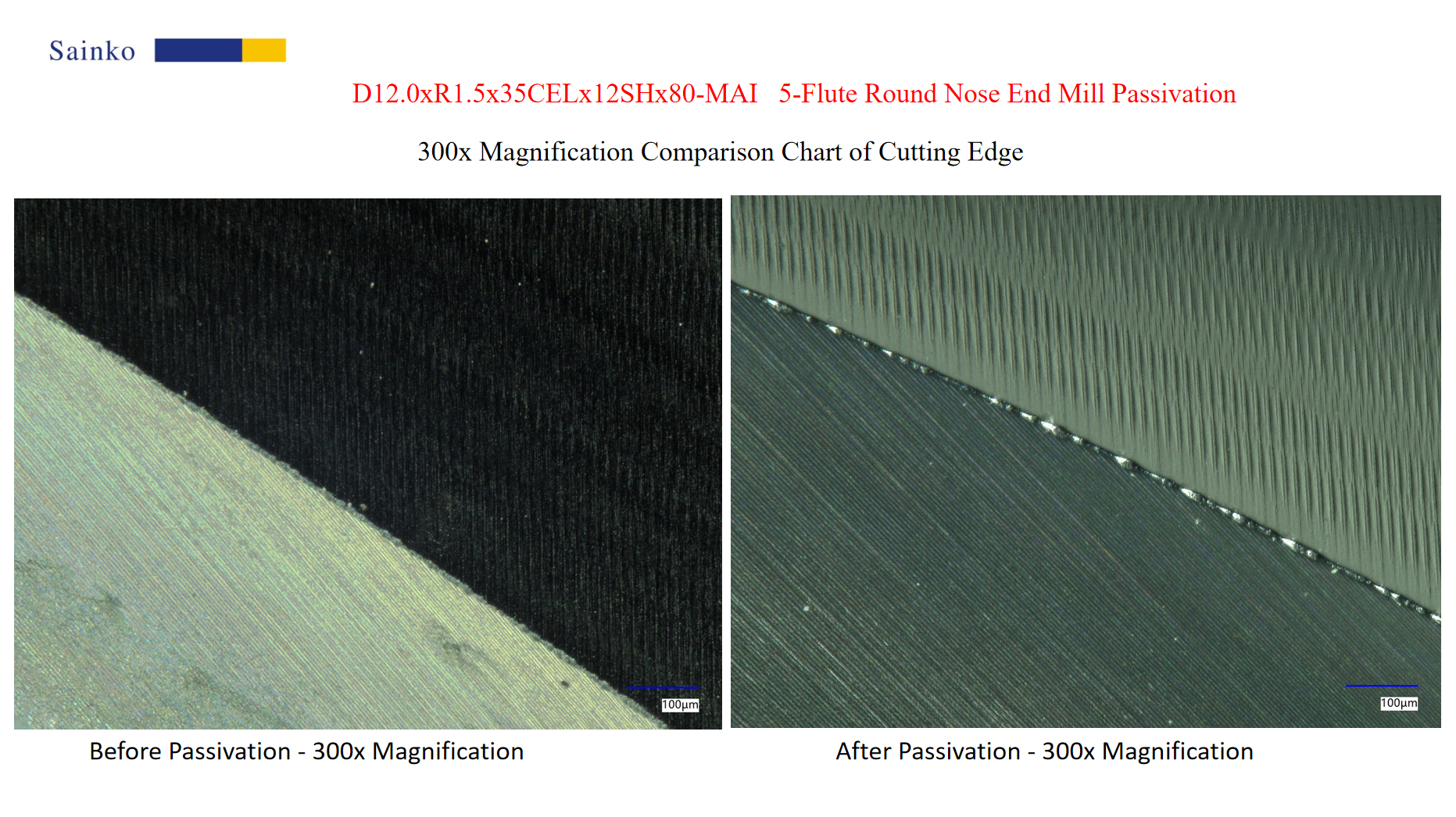

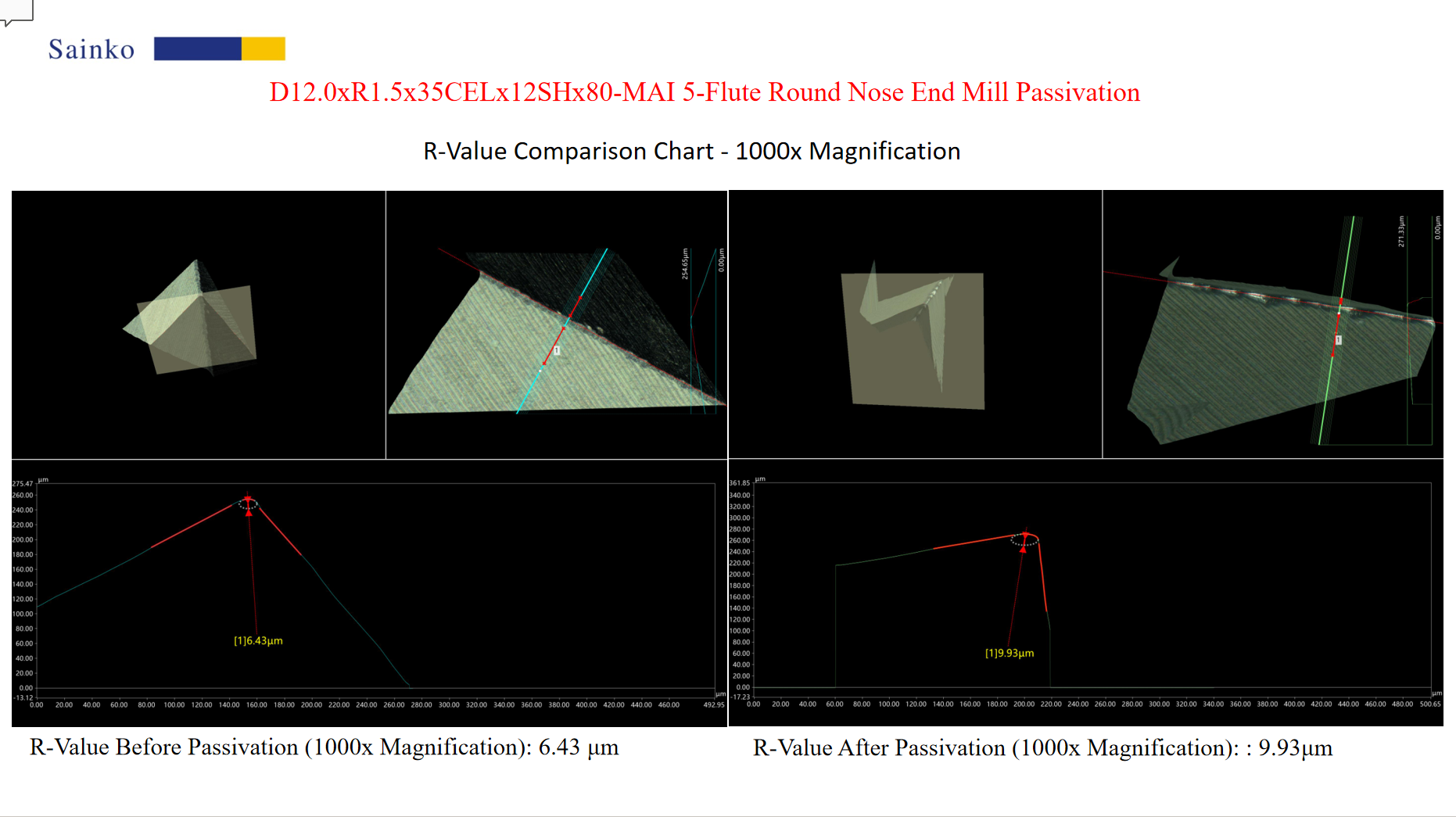

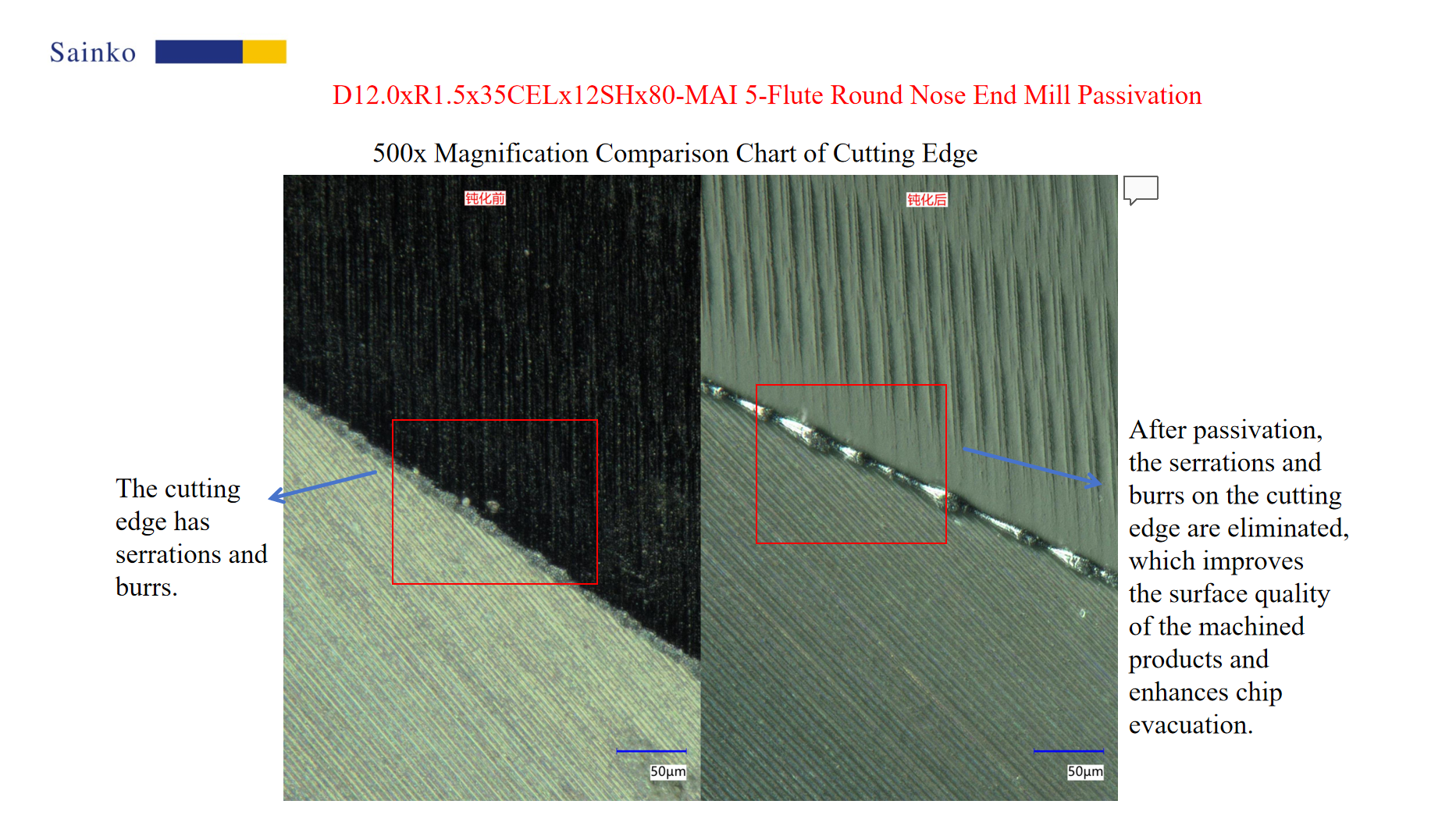

This test was conducted on four (4) pieces of 5-flute round nose end mills. The PL-24AX model equipment and 15000-L abrasive were used for the passivation process.Before passivation, the passivation value of a single end mill was 6.43 μm. After the passivation process (29 seconds per unit), detection via Keyence equipment showed that the passivation value stabilized at 9.93 μm.A comparison of the cutting edge conditions under a 500x microscope revealed that, before passivation, the cutting edge had obvious serrations and burrs; after passivation, the cutting edge became smooth and flat, with serrations and burrs eliminated. This improvement can effectively enhance the surface quality of machined products and the chip evacuation performance.